PERMA-CHINK SYSTEMS WOOD CLEANING PRODUCTS

Log Wash™ – A general purpose, low-pH cleaner concentrate for removing dirt, grime, pollen, stains from surface mold and mildew from bare wood surfaces and existing finishes. Log Wash will also remove some types of brown stains and lighten the color of bare wood. Log Wash is not effective for removing grayed, oxidized wood fibers. Whenever bare wood surfaces are left exposed to the elements for more than seven days, the surfaces should be cleaned with a solution of Log Wash before the first coat of finish is applied. Wood ReNew™ – A concentrated powder that is dissolved in water and applied to bare wood. When used with a pressure washer, it will remove gray, oxidized surface wood as well as dirt, pollen, mold and mildew. Although Wood ReNew usually lightens the color, it can occasionally darken the wood depending on the wood species and the types of chemicals previously applied. Wood ReNew is the product of choice for removing mill glaze from new wood surfaces.

CLEANING EXTERIOR BARE WOOD SURFACES

NEW LOG HOMES

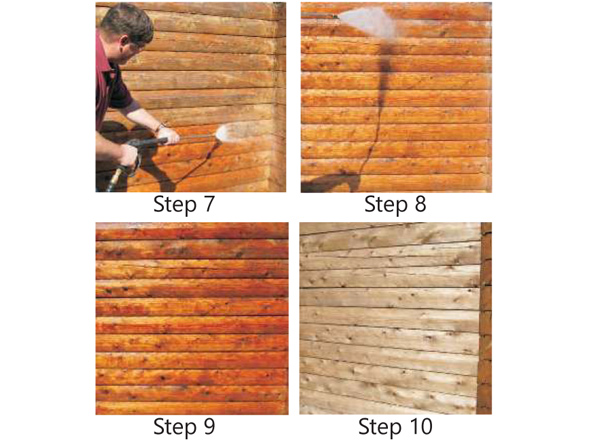

Step 1: If the wood has not grayed, wash the surface with a two cups per gallon Log Wash solution and a pressure washer no more than seven days prior to staining. Apply and clean from the bottom up and rinse from the top down. Rinse well and allow the wood to dry.

Step 2: If there are signs of gray weathered wood, use Wood ReNew according to the application instructions along with a pressure washer.

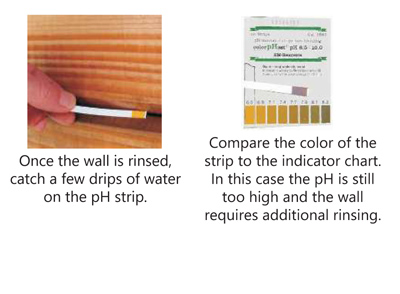

Step 3: If after Steps 1 or 2 there are still dark streaks or discolorations on the surface, use a solution of Oxcon™ oxalic acid on the entire wall according to the directions for use. Be sure to dilute the Oxcon concentrate with four parts water. Apply the solution from the bottom up, begin washing it off starting at the bottom then rinse thoroughly from the top down. Be sure to completely rinse the Oxcon solution off the wall and allow the wood to dry before staining. Never use Oxcon unless it is absolutely necessary.

NEW LOG SIDING

New log siding must always be cleaned, since it presents an especially difficult challenge to a finish system. Typically used in high exposure locations such as dormers and gable ends, siding is often manufactured from lower quality wood than logs, and frequently green wood. This makes siding more susceptible to twisting, warping, and cracking. Since siding does not have the high thermal mass of full logs, during the summer months its temperature can range from 70ºF to 160ºF or higher during the course of one day. This puts a lot of mechanical stress on the siding and its finish, resulting in small fissures forming on the surface. Rainwater can then enter these fissures and get into the wood, behind the finish. Log siding is typically milled quite smooth and often has a mill glaze on the surface, which if not removed, prevents the proper adhesion of the finish.

Step 1: To remove mill glaze and prepare siding for the first coat of finish, clean and pressure wash the surface of the siding using Wood ReNew no more than seven days prior to staining. Apply the solution of Wood ReNew and pressure wash from the bottom up, and rinse from the top down. Allow the siding to dry before staining.

Leave a comment